00:01 Introduction

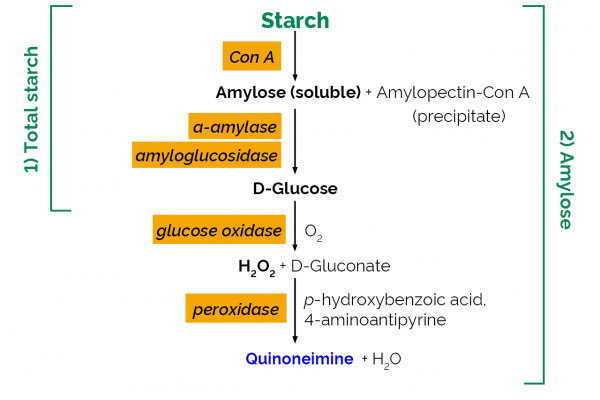

01:16 Theory of the Analytical Procedure

02:33 Kit Content & Reagent Preparation

06:15 Weighing of Samples

06:44 A. Starch Pretreatment

12:04 B. Precipitation of Amylopectin with Con A & the Determination of Amylose

16:11 C. Determination of Total Starch

18:35 Determination of D-Glucose in Amylose & Total Starch Fractions

20:37 Calculation of Amylose Content

| Content: | 100 assays per kit |

| Shipping Temperature: | Ambient |

| Storage Temperature: |

Short term stability: 2-8oC, Long term stability: See individual component labels |

| Stability: | > 2 years under recommended storage conditions |

| Analyte: | Amylopectin, Amylose |

| Assay Format: | Spectrophotometer |

| Detection Method: | Absorbance |

| Wavelength (nm): | 510 |

| Signal Response: | Increase |

| Limit of Detection: | Amylose 5-95% of total starch content |

| Total Assay Time: | ~ 120 min |

| Application examples: | Cereal starches, flours, pure starches and foods. |

| Method recognition: | Novel method |

The Amylose/Amylopectin test kit is suitable for the measurement and analysis of amylose/amylopectin ratio and content in cereal starches and flours. Based on a Con A precipitation procedure.

See our full list of polysaccharide test kits.

- Very cost effective (cost per test)

- All reagents stable for > 12 months after preparation

- Only enzymatic kit available

- Accurate and reliable amylose / amylopectin ratio determination

- Simple format

- Standard included

McCleary, B. V., Charnock, S. J., Rossiter, P. C., O’Shea, M. F., Power, A. M. & Lloyd, R. M. (2006). Journal of the Science of Food and Agriculture, 86(11), 1648-1661.

Procedures for the measurement of starch, starch damage (gelatinised starch), resistant starch and the amylose/amylopectin content of starch, β-glucan, fructan, glucomannan and galactosyl-sucrose oligosaccharides (raffinose, stachyose and verbascose) in plant material, animal feeds and foods are described. Most of these methods have been successfully subjected to interlaboratory evaluation. All methods are based on the use of enzymes either purified by conventional chromatography or produced using molecular biology techniques. Such methods allow specific, accurate and reliable quantification of a particular component. Problems in calculating the actual weight of galactosyl-sucrose oligosaccharides in test samples are discussed in detail.

Hide AbstractMcCleary, B. V., Gibson, T. S. & Mugford, D. C. (1997). Journal of AOAC International, 80, 571-579.

An American Association of Cereal Chemists/AOAC collaborative study was conducted to evaluate the accuracy and reliability of an enzyme assay kit procedure for measurement of total starch in a range of cereal grains and products. The flour sample is incubated at 95 degrees C with thermostable alpha-amylase to catalyze the hydrolysis of starch to maltodextrins, the pH of the slurry is adjusted, and the slurry is treated with a highly purified amyloglucosidase to quantitatively hydrolyze the dextrins to glucose. Glucose is measured with glucose oxidase-peroxidase reagent. Thirty-two collaborators were sent 16 homogeneous test samples as 8 blind duplicates. These samples included chicken feed pellets, white bread, green peas, high-amylose maize starch, white wheat flour, wheat starch, oat bran, and spaghetti. All samples were analyzed by the standard procedure as detailed above; 4 samples (high-amylose maize starch and wheat starch) were also analyzed by a method that requires the samples to be cooked first in dimethyl sulfoxide (DMSO). Relative standard deviations for repeatability (RSD(r)) ranged from 2.1 to 3.9%, and relative standard deviations for reproducibility (RSD(R)) ranged from 2.9 to 5.7%. The RSD(R) value for high amylose maize starch analyzed by the standard (non-DMSO) procedure was 5.7%; the value was reduced to 2.9% when the DMSO procedure was used, and the determined starch values increased from 86.9 to 97.2%.

Hide AbstractGibson, T. S., Solah, V. A. & McCleary, B. V. (1997). Journal of Cereal Science, 25(2), 111-119.

A modified procedure for the determination of amylose in cereal starches and flours based on complex formation between the lectin concanavalin A (Con A) and amylopectin has been developed and characterised. The assay format is suitable for multi-sample analysis, allowing the analysis of up to 20 samples per day. In the procedure, the amylopectin in a solubilised, lipid-free starch sample is precipitated by reaction with Con A and removed by centrifugation. The amylose remaining in the supernatant is then determined after amylolytic hydrolysis to glucose and expressed as a proportion (%) of the glucose derived from amylolytic hydrolysis of the total starch in a separate aliquot of the solubilised sample (i.e. prior to Con A treatment). The Con A procedure correlates well (r>0•993) with existing Con A-based and iodine-based procedures and yields a linear standard curve for starch samples containing from ∼0 to ∼100% amylose. Advantages of this modified Con A procedure for amylose determination include its applicability to flour samples without the need for prior starch purification; it allows the simultaneous estimation of total starch and does not require a calibration curve. Repeated analyses of a set of samples yielded repeatability (within laboratory) relative standard deviations of <5% for pure starches and ∼10% for flours. A commercially available assay kit has been developed to facilitate the use of the Con A procedure in routine amylose determinations.

Hide AbstractDelayed effect of superfine particle size of oat bran on starch retrogradation and hydrolysis of gluten-free rice bread during short-term storage.

Zhang, J., Wang, L., Tong, L., Xu, B., Wang, P., Ren, C., Guo, L & Qiu, J. (2025). Journal of Cereal Science, 124, 104216.

Oat bran addition to rice bread results in quality deterioration especially during storage, but its superfine particle size probably relieves this side effect. This study focuses on the gluten-free and rice starch-based bread. The effects of different particle sizes at medium (MOB, 359.67 μm), fine (FOB, 153.67 μm) and superfine (SOB, 35.77 μm) on the short-term storage quality of rice bread was confirmed. Oat bran addition affected pasting properties of rice flour, leading to a significant decrease in values of final viscosity and setback, which was intensified much more by the smaller particle sizes. The decrease in particle size of oat bran also led to an increase in brightness and whiteness values of rice bread. Gas-holding capacity of rice bread was reduced by MOB and FOB, including specific volume, gas cell diameter and volume, but SOB reversed this reduction and recovered to the same level as control bread. SOB mitigated the increase in bread firmness during storage and led to the highest springiness while the lowest baking loss. The water-binding capacity of rice bread with SOB was much higher than that with MOB and FOB, according to the moisture migration analysis. The inhibition of water evaporation by SOB during storage further delayed the amylopectin retrogradation and starch recrystallization. Additionally, SOB prevented the rice starch hydrolysis, exhibited an increase in RS (35.39 %), which was much higher than those of MOB (23.30%) and FOB (25.30%). These findings supported the efficient inhibition of SOB on rice bread staling.

Hide AbstractDevelopment of a Simple Protocol to Assess Glucose Release After In Vitro Digestion, Allowing Comparison of Starchy Foods.

Montebugnoli, T., Antonelli, G., Chiarello, E., Rivera, N. S., Camporesi, G., Danesi, F. & Bordoni, A. (2025). Food Science & Nutrition, 13(6), e70323.

Diets including foods with low glycemic index have been proposed to reverse the rising incidence of obesity and type 2 diabetes. Unfortunately, many common starchy staple foods have a high glycemic index. Several strategies for producing foods with low glycemic index have been proposed, but their application by the food industry is limited by the difficulty and cost of measuring GI in vivo. The aim of the present study was to develop a simple and reliable protocol to assess glucose release after in vitro digestion, and to use it to compare commercial starchy foods. To this purpose, a final starch digestion step was included in the INFOGEST in vitro digestion protocol by adding the enzyme amyloglucosidase, which mimicked the action of brush border enzymes. Glucose release was evaluated in five starchy foods (flour, bread, crackers, and durum wheat pasta and gluten‐free pasta), available on the market in two forms produced by the same company, one standard and one rich in fiber (> 6 g/100 g). Glucose release was evaluated 0, 30, 60, and 120 min after the addition of amyloglucosidase. In all foods, glucose release at T0 was very low, confirming that starch digestion by amylases is incomplete. Excluding flours, the lowest and highest amounts of glucose release (28.29 and 49.36 g/50 g of available carbohydrates) were detected in durum wheat pasta and gluten‐free pasta, respectively, confirming the high glycemic index previously detected in many gluten‐free products. Notably, when glucose release was expressed as g/50 g of available carbohydrate, the impact of fiber content was negligible. Although the in vitro assessment of glucose release should not be confused with the glycemic index, the herein reported protocol can help predict the impact of foods on glycemia, facilitating the formulation of healthier products.

Hide AbstractHydrogen bond density and glass-transition temperature govern gelatinization and gel rheology in cereal and tuber starches.

Renzetti, S., Henket, J., Raaijmakers, E., van den Hoek, I. & van der Sman, R. (2025). Current Research in Food Science, 10, 101101.

The gelatinization behaviour, pasting properties, and rheology of potato, cassava, rice, wheat, and waxy corn starches were studied. Gelatinization behaviour was examined at different starch-to-water ratios using differential scanning calorimetry to construct state diagrams of melting. The obtained onset, peak, and end temperatures of gelatinization were described using the Flory-Huggins theory for biopolymer melting. The validity of the obtained diagrams was tested against literature data, including gelatinization in different sugar solutions for all starches. Water-sugar mixtures were treated as a single solvent by considering the volumetric density of hydrogen bonds in the sugar solutions (). All literature data collapsed into the melting diagrams, except for Tonset at high sugar concentrations, due to phase separation between starch-rich and sugar-rich phases. The pasting properties and the rheology of freshly prepared starch gels were analyzed at three concentrations (5, 8, and 11% w/w) in water, revealing differences among the starches as a function of concentration. However, G′ and G″ values obtained from frequency sweeps scaled with the computed Tg/T, based on amylose concentrations. Cereal and tuber starches exhibited distinct relationships with Tg/T. Notably, literature data collected under similar experimental conditions aligned with the scaling observed in this study, despite differences in ingredient sourcing. Overall, this study provides insights into the physicochemical principles governing gelatinization and rheological behaviour in starches from diverse botanical sources. The findings offer a universally applicable understanding that can aid in designing cereal- and starch-based food formulations.

Hide AbstractAmaranth-alginate hydrogels: rheological, textural, and sensory properties for gluten-free noodles.

Lux, T., Krapf, J., Reimold, F., Lochny, A., Erdoes, A. & Floeter, E. (2025). Future Foods, 11, 100676.

Gluten-free products are receiving growing attention, with amaranth, a nutrient-rich pseudocereal widely used in their formulation. Due to the absence of gluten, hydrocolloids such as alginates are often added to enhance structure and texture. This study examines the impact of different flour-water ratio and alginate addition on the functional, rheological, and sensory properties of amaranth-based hydrogels. Pregelatinized amaranth flour (AS) was used to prepare suspensions with sodium alginate (ASA) and calcium-induced gelation applied to create strand-formed noodles (AN). Optimizing water availability was crucial in shaping the mechanical properties and gel structure. SEM analysis revealed that interactions between gelatinized amylose and alginate compacted the gel matrix, enhancing strength and stability. Texture analysis showed a strong negative correlation (r = -0.81) between gel stiffness and cutting force. Sensory testing indicated that higher water content improved texture smoothness and flavor neutrality. Optimal flour-water ratios (1:6, 1:8, 1:10) produced firm, cohesive noodles with desirable mouthfeel and minimal retrogradation. Overall, this work demonstrates the potential of pregelatinized amaranth flour and alginate to create high-quality gluten-free noodles with customized sensory and structural attributes, offering valuable insights for future product development.

Hide AbstractMorphological and nutritional responses of sorghum to variable irrigation levels and nitrogen doses.

Ciftci, B., Varol, I. S., Akcura, S., Kardes, Y. M., Karaman, S. & Kaplan, M. (2025). PLoS One, 20(5), e0323901.

This study aimed to determine the effects of different irrigation levels (50%, 75%, and 100% of ETo values calculated using evaporation from Class-A pan) and nitrogen doses (0, 90, 180, and 270 kg ha ⁻ ¹) on yield, yield components, and the nutritional properties of sorghum grains. According to the research results, increasing irrigation and nitrogen fertilization levels enhanced plant height, thousand-grain weight, grain number per panicle, grain weight per panicle, and grain yield. The highest grain yield (7120 kg ha ⁻ ¹) was obtained with 100% irrigation and 180 kg ha ⁻ ¹ N application. While increasing irrigation levels increased oil content, higher nitrogen doses caused a decrease for it. The highest oil content (6.64%) was recorded with 100% irrigation and 0 kg ha ⁻ ¹ N application. Protein content increased with irrigation and nitrogen applications, reaching the highest level (11.85%) with 100% irrigation and 270 kg ha ⁻ ¹ N application. Higher irrigation levels also increased total starch and phytic acid content. Among nitrogen applications, the dose of 270 kg ha ⁻ ¹ resulted in the maximum total starch (77.29%) and phytic acid content (1.83%). The ratio of resistant starch (RS) was found to be high at 50% irrigation with low nitrogen doses, indicating an inverse relationship with the total starch content. Both irrigation and nitrogen applications significantly affected the ratios of oleic and linoleic acids. Specifically, increased irrigation raised the linoleic acid content, while nitrogen applications enhanced the oleic acid content. Additionally, as irrigation levels increased, the contents of potassium (K), magnesium (Mg), iron (Fe), phosphorus (P), and zinc (Zn) also increased. Conversely, the levels of calcium (Ca) and manganese (Mn) decreased. Generally, higher nitrogen doses resulted in increased mineral content, with the highest levels of magnesium, iron, and zinc observed at nitrogen doses between 180 and 270 kg ha ⁻ ¹. According to the research results, the most suitable irrigation level for optimizing high yield and grain nutritional properties was determined to be 100%, with a nitrogen dose of 180–270 kg ha ⁻ ¹. These findings will contribute to future studies on different sorghum varieties under varying climate and soil conditions.

Hide AbstractExploring the influence of rice proteins on the gel and digestive properties of rice noodles: based on the interaction with starch.

Wang, Y., Tang, N., Geng, D. H., Asiamah, E. & Cheng, Y. (2025). International Journal of Biological Macromolecules, 318, 144972.

The structural interactions between starch and rice proteins play a pivotal role in shaping the textural and nutritional properties of rice noodles. This study systematically explored the multi-scale interactions between fractionated rice starch particles (classified by mesh size) and rice proteins during gel network formation, with a particular focus on their combined effects on rheological behavior and enzymatic digestibility. Results demonstrated that rice proteins significantly reduced starch pasting viscosity (from 3160 cP to 1628 cP) while enhancing shear stability, especially in systems containing smaller starch granules (<75 μm). Microstructural analysis revealed dual stabilization mechanisms: (1) hydrogen bond-mediated protein-starch adhesion (FTIR peak at 3285 cm−1), which preserved gel elasticity, and (2) the formation of V-type amylose-protein complexes (XRD peak at 20° 2θ), which improved structural stability and increased resistant starch content (from 20.0% to 37.0%). Notably, the interplay between starch particle size and rice proteins primarily influenced overall digestive outcomes rather than initial hydrolysis rates. Sub-200-mesh starch particles exhibited a 24.9% faster digestion within the first 30 min; however, in the presence of rice proteins, total digestibility was reduced by 13.55%, underscoring the regulatory role of protein-starch interactions in modulating enzymatic accessibility. These findings highlight that rice proteins influence starch digestion not by directly inhibiting enzymatic reactions but by introducing steric hindrance that restricts enzyme access. The synergistic effects between proteins and starch components provide a novel strategy for developing texturally resilient rice noodles with a reduced glycemic response, offering valuable insights for the formulation of functional rice-based products.

Hide AbstractThe multifunctional ascorbate peroxidase MoApx1 secreted by Magnaporthe oryzae mediates the suppression of rice immunity.

Liu, M., Guo, Z., Hu, J., Chen, Y., Chen, F., Chen, W., Wang, W., Ye, B., Yang, Z., Li, G., Liu, X., Zhang, H.,Wang, P. & Zhang, Z. (2025). The Plant Cell, 37(7), koaf146.

Fungi secrete effector proteins, including extracellular redox enzymes, to inhibit host immunity. Redox enzymes have been hypothesized to inhibit host reactive oxygen species (ROS); however, how they suppress host immunity remains unknown. We characterized an extracellular ascorbate peroxidase (MoApx1) that is secreted into rice chloroplasts by the rice blast fungus Magnaporthe oryzae. MoApx1 displays multifunctional capabilities that significantly contribute to fungal virulence. Firstly, MoApx1 neutralizes host-derived H2O2 within the chloroplast through its peroxidase activity, thereby inhibiting chloroplast ROS (cROS)-mediated defense responses. Secondly, MoApx1 targets the photosystem I subunit OsPsaD, disrupting photosynthetic electron transport to further suppress cROS production. Most importantly, MoApx1 has evolved a fungal-specific starch-binding domain that binds host starch, inhibiting its degradation and disrupting the energy supply required for host resistance. Our findings underscore the importance of a novel multifaceted strategy, potentially widely employed by other fungal pathogens, in suppressing host immunity during host–microbe interactions.

Hide AbstractOptimising Gelatinisation-Ultrasound Processing for Starch Nanoparticle Production from Cassava, Quinoa, and Faba Bean: Structural and Functional Characterisation.

Halim, A., Torley, P., Farahnaky, A. & Majzoobi, M. (2025). Food Hydrocolloids, 169, 111644.

This study optimised the production of starch nanoparticles (SNPs) from cassava, quinoa, and faba bean starches using a combined gelatinisation-ultrasound treatment. Response surface methodology with a Box-Behnken design was used to optimise ultrasound parameters (power: 140-700W, sonication time: 10-30 min, and starch concentration: 1-5%). Optimised conditions (420W, 20 min, 3% concentration) effectively produced uniform nanoparticles (65.7-87.6 nm) with narrow size distributions (PDI: 0.317-0.410) across all three botanical sources, achieving a substantial 99.7% reduction in particle size compared to native granules. The modified SNPs displayed altered crystallinity patterns (transitioning from type-A and C to type-V) with significantly reduced relative crystallinity (60-65% reduction) and amylose content (29.6-58.7% reduction), while maintaining their fundamental chemical structure as confirmed by FTIR and NMR analyses. Notably, the SNPs exhibited substantially increased water solubility (95.1-98.2% compared to 5.3-10.4% for native starches), improved oil absorption capacity (87.2-105.5% versus 58.9-69.5%), and significantly increased slowly digestible starch fractions (up to 63.8% in faba bean SNPs). This optimised treatment provides a sustainable, chemical-free method for producing functional starch nanoparticles with tailored digestibility profiles and enhanced technological properties for diverse food applications.

Hide AbstractOsMYBR1, a 1R-MYB Family Transcription Factor Regulates Starch Biosynthesis in Rice Endosperm.

Huang, K., Chen, L., Jiao, G., Ruan, Z., Li, X., Tang, S., Hu, P. & Wei, X. (2025). Life, 15(6), 962.

Starch is the primary component of the endosperm and plays a crucial role in rice quality. Although the enzymes involved in starch synthesis have been extensively studied, the transcription factors that regulate these enzymes remain largely unknown. Here, we identified a MYB family transcription factor, OsMYBR1, that regulates starch biosynthesis in rice. OsMYBR1 is highly expressed during endosperm development. Mutations of OsMYBR1 result in reduced grain thickness and a decrease in 1000-grain weight. The endosperm of osmybr1 mutants exhibit rounded and loosely packed starch granules, decreased amylose content, altered fine structure of amylopectin, and modified physicochemical properties. The analysis of RT-qPCR showed that the expression of several starch-synthesis enzyme-coding genes (SSEGs), including OsGBSSⅠ, OsAGPL1, OsAGPL2, OsBEⅡb, OsISA1, PHOL, and OsSSⅢa, is altered in osmybr1 mutants. Further experiments indicated that OsMYBR1 directly binds to the promoters of OsGBSSⅠ, OsAGPL1, OsAGPL2, OsISA1, OsBEⅡb, and PHOL, resulting in an increase in the expression of OsGBSSⅠ but a decrease in the expression of OsAGPL2, OsISA1, and OsSSⅢa. In contrast, OsMYBR1-overexpressing endosperm appears normal, with starch granule morphology, increased amylopectin content, and improved alkali spreading value, indicating enhanced rice eating and cooking quality (ECQ). These findings suggest that the overexpression of OsMYBR1 could be a promising strategy for improving rice ECQ.

Hide AbstractEffect of Infrared Heat‐Moisture Treatment and Cooling Rate on the Material Properties of Amylose–Lipid Complex Nanomaterials.

Maphumulo, N. G., Masanabo, M. A., Ray, S. S. & Emmambux, M. N. (2025). Starch‐Stärke, e70062.

There are limited food-compatible nanomaterials to be used in foods, or most of them are not considered as edible or clean label. Isolated amylose–lipid complex (ALC) nanomaterials were subject to infrared heat moisture treatment (IR-HMT) at 110°C for 1, 2, and 3 h continuously or IR-HMT for 1 h followed by different cooling systems (room temperature, refrigeration temperature, and liquid nitrogen) and repeated two more times. Differential scanning calorimetry (DSC) revealed that IR-HMT and an increase in cooling rates resulted in ALC nanomaterials with higher endothermic peak temperatures (Tp) (109–112°C) and the presence of Type II crystallites. Notably, IR-HMT and cooling with room temperature resulted in Type IIa ALC (Tp = 109°C), while cooling with refrigeration temperatures and liquid nitrogen resulted in Type IIb ALC nanomaterials (110–112°C). X-ray diffraction (XRD) revealed higher crystallinity (up to 21%) for IR-HMT ALC with different cooling systems compared to their untreated counterparts (13%). Furthermore, faster cooling resulted in ALC nanomaterials with higher crystallinity compared to slower cooling rate. IR-HMT resulted in ALC nanomaterials with lower viscosity compared to untreated ALC as observed from flow properties. Furthermore, they displayed lower water absorption and solubility indices, suggesting that IR-HMT and different cooling systems led to molecular changes in ALC nanomaterials that affected their properties.

Hide AbstractAnalysis of Short‐and Long‐Term Two‐Mode Retrogradation of Corn Starch During Refrigerated Storage.

Ninomiya, K., Ozawa, N., Okawa, Y., Yamaguchi, Y., Kumagai, H. & Kumagai, H. (2025). Cereal Chemistry, 102(3), 653-660.

Background and Objectives: Starchy foods stored at low temperatures for long periods undergo hardening due to starch retrogradation (crystallization). However, a method for measuring the degree of starch retrogradation has not been sufficiently established yet. In this study, two modes of starch retrogradation were kinetically investigated for short- and long-term retrogradation to assess starch retrogradation with high accuracy. The retrogradation degree of corn starch (CS) was assessed using the β-amylase-pullulanase (BAP) method, differential scanning calorimetry (DSC), mechanical measurements, and water separation ratio. Findings: By improving the measurement precision of the BAP method, starch retrogradation could be evaluated with high precision, even at high CS concentrations. The time course of enthalpy change (ΔH) that accompanies the melting of recrystallized starch crystals due to retrogradation for 0–25 days using a single Avrami's formula, the regression curve had a correlation coefficient R of approximately 1, but the χ² value was considerably larger than that for 0–5 days. Using two combined Avrami's formulae had a correlation coefficient R of 1 and a small value of χ², which well described the change in ΔH over time. Additionally, Avrami's analysis revealed two crystal modes separated by approximately 5 days. Mechanical measurements and water separation ratio results also supported the existence of two crystallization modes separated by approximately 5 days. Conclusions: The BAP method and DSC could be used to assess the degree of starch retrogradation with high accuracy. The two combined Avrami's formulae were found to kinetically discriminate the switch from short- to long-term retrogradation.

Hide AbstractComparative study on structural characterization, physicochemical properties, and in vitro probiotic activities of resistant starch from different varieties of Euryale ferox.

Qu, C., Yu, D., Jing, Z., Gu, S., Wang, Y., Xie, W. & Wu, Q. (2025). Food Chemistry: X, 28, 102572.

Euryale ferox (EF), a highly nutritious food, is an excellent source of resistant starch (RS). This study compared the structure, physicochemical properties, and probiotic activities of RS from North (NEFRS) and South EF (SEFRS). NEFRS exhibited a higher RS content (~10%) than SEFRS (~4%) and demonstrated superior crystallinity (21.66%), thermal stability (ΔH = 21.85 J/g), and molecular order, whereas SEFRS contained more double helices (ΔH = 4.17 J/g). Both displayed type A crystalline structures, with RS5 amylose-lipid complexes being more abundant in NEFRS during growth. Gas chromatography-mass spectrometry identified bound fatty acids, including palmitic, linoleic, trans-oleic, and stearic acids, confirmed through in vitro synthesis. Probiotic assays revealed EFRS enhanced the growth of Bifidobacterium and Lactobacillus acidophilus, while NEFRS exhibited stronger inhibition against Escherichia coli and Staphylococcus aureus. Overall, this study systematically elucidated the EFRS differences between two species, providing valuable insights into functional product development and EF deep processing.

Hide Abstract